Furniture maker looks to improve working conditions

The company was looking to save money on running costs and improving operator working conditions by reducing noise. Verco in Buckinghamshire, UK, follows an ECO Policy for green environmental considerations and these benefits improved their carbon foot print. They were using electric motor driven vacuum pumps on their routing machines that were loud, generated a lot of heat and were expensive to operate and maintain.

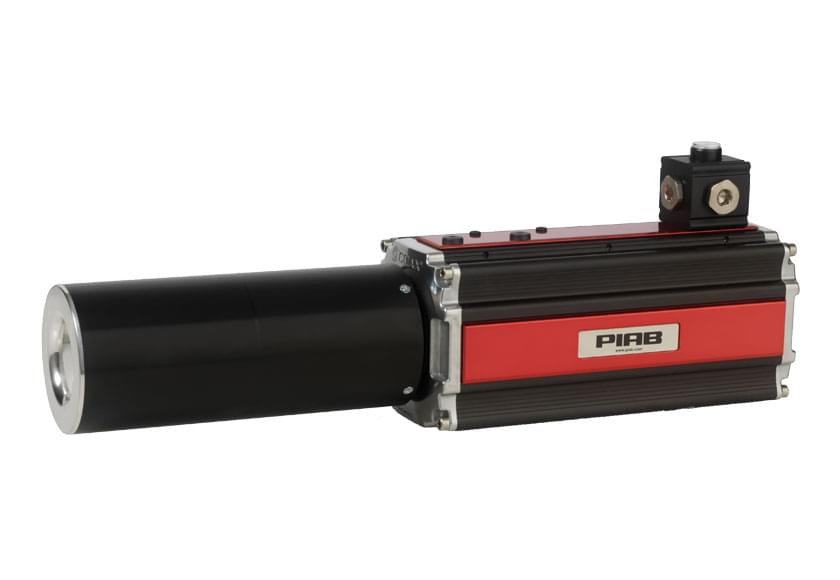

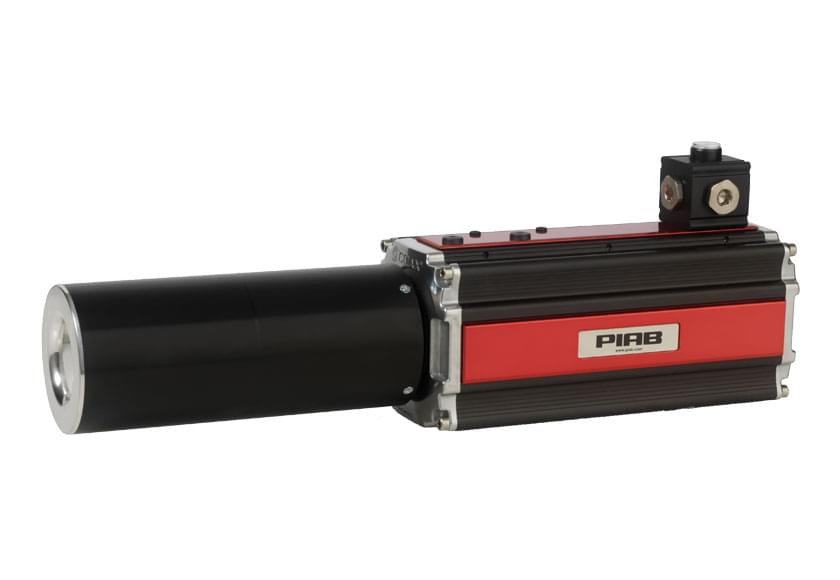

By using two Piab P6040 air-driven vacuum pumps with energy-efficient COAX® technology to replace the electric motor driven vacuum pumps for holding down wood on the twin bed horizontal router machine, Piab were able to offer a more effective solution. The P6040 vacuum pump is whisper-quiet in operation and generates no heat at all; the operator was provided a clean, comfortable, quiet work environment. And most importantly, less energy would be used on site reducing the company’s utilities bill.

Compared to the electric motor-driven vacuum pumps, the P6040 unit clearly out performed, achieved deeper vacuum, had a faster flow rate, and sped up the vacuum forming process. Control of the air supply based on process demand meant the P6040 operated on a 10% cycle that offered predicted energy savings and a quick payback.

“The Piab unit offers a simple high performance vacuum solution compared to our existing regenerative blowers. Reduced energy costs, smaller footprint and a fit-and -forget installation made it an ideal choice”, Mick Pitwell said of Verco Office Furniture Ltd.

BIBUS Belarus: a reliable supplier of goods from leading manufacturers in the field of pneumatics, hydraulics and mechatronics

BIBUS Belarus: a reliable supplier of goods from leading manufacturers in the field of pneumatics, hydraulics and mechatronics

When it comes to…

Merger of Altra Motion into the Regal Rexnord organization

Following the recent merger of Altra Motion into the Regal Rexnord organization we inform you thta all former Altra Motion companies (Stromag,…

Technology Group Voith takes over the company ARGO-HYTOS.

Technology Group Voith takes over the company ARGO-HYTOS. Based in Baar, Switzerland, the company develops and produces components for hydraulics and…